Leema Abd Al-Rahman Al-Makhadmeh

Jordan University of Science and Technology, Jordan

Title: Oil shale combustion under oxy-fuel conditions

Biography

Biography: Leema Abd Al-Rahman Al-Makhadmeh

Abstract

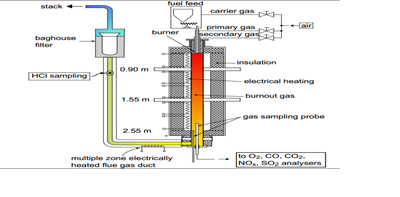

Direct combustion of Jordanian oil shale under oxy-fuel conditions was investigated. Unstaged and staged air-firing as well as combustion at 27% O2/73% CO2 (OF27) was conducted successfully. A 20 kW vertical reactor was used at a combustion temperature of 1200 oC. Oil shale-N conversion rate to NO is higher during unstaged air-firing than oxy-fuel combustion; they are 27% and 15% for air-firing and OF27 combustion, respectively. NOx emission reduced efficiently by adopting staged combustion technology under oxy-fuel conditions as well as air-firing. In addition, the reduction of simulated recycled NO has been investigated. The actual situation has been simulated by injecting NO in the reactor through the burner during OF27 combustion. The reduction of the injected NO is more efficient with staging compared to unstaged combustion mode; 100% reduction of the injected NO during staged OF27 combustion is registered while for unstaged OF27 combustion it ranges from 57% to 65%. The high sulfur content in Jordanian oil shale is considered one of the biggest challenges for its utilization. The oil shale-S conversion rate to SO2 is lower during unstaged OF27 combustion compared to air-firing; they are 69% and 49% for air-firing and OF27 combustion, respectively. For both unstaged combustion modes, direct limestone injection at different molar Ca/S ratios has been investigated; SO2 emissions are reduced significantly by direct limestone injection. At Ca/S molar ratio of 3, the desulfurization efficiencies are 100% and 95% for OF27 combustion and air-firing, respectively.

Recent Publications:

- Al-Makhadmeh L., J. Maier, MA Batiha and G. Scheffknecht (2017) Oxy-fuel technology: Oil shale desulphurisation behaviour during staged combustion. Fuel, 190, 229–236. Online on 26/11/2016.

- Al-Makhadmeh L., MA Batiha (2015) Removal of Iron and Copper from Aqueous Solutions Using Jordanian Kaolin and Zeolitic Tuff. Desalination and Water Treatment, 2015. 1-14.

- Al-Makhadmeh L., J. Maier, M. Al-Harahsheh and G. Scheffknecht (2015) Oxy-fuel technology: Oil shale desulphurisation behaviour during unstaged combustion. Fuel, 158, 460–470.

- Mohammad Al-Harahsheh, Awni Al-Otoom, Leema Al-Makhadmah, Ian E Hamilton, Sam Kingman, and Sameer Al-Asheh (2015) Pyrolysis of Poly(vinyl chloride) and –Electric Arc Furnace Dust Mixtures. HAZMAT, Jun 25; 299: 425-436.

- Al-Makhadmeh L., J. Maier and G. Scheffknecht (2014) Oxy-fuel technology: NO Reduction During Oxy-Oilshale combustion. Fuel, 128, 155–161.